L&M Radiator | Industrial & Commercial Heat Transfer Solutions

SOLVING PROBLEMS THAT OTHERS CAN’T

BY DOING THINGS THAT OTHERS WON’T

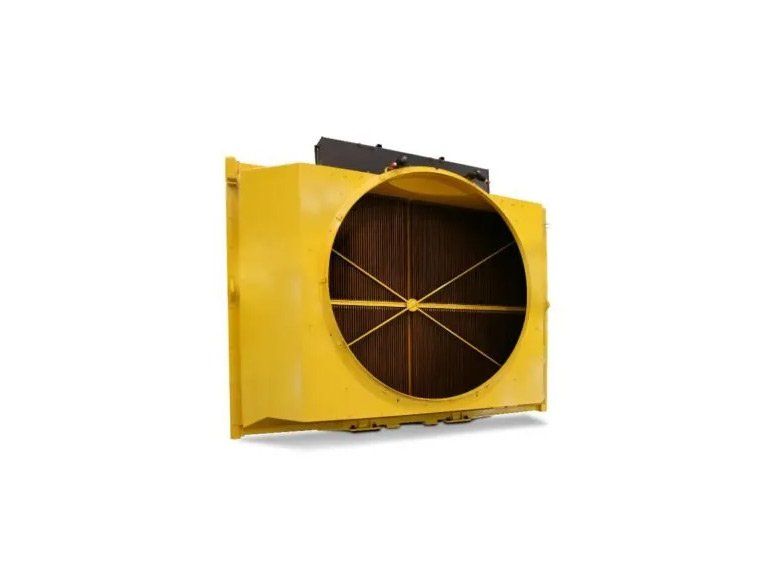

MESABI® heat transfer solutions are engineered and designed with The MESABI® Difference in mind. Built to optimize performance, simplify maintenance, withstand any conditions and reduce downtime – MESABI® products deliver the competitive edge you want. The MESABI® Difference separates our products from the rest of the pack. This difference is rooted in solving the problems that others can’t by taking into account the aspects that others won’t. By welcoming challenges from around the world, we can develop industry-leading heat exchangers using the knowledge gained throughout our more than 65-year history.

Our flexible core heat exchangers have been the workhorses of your mine sites, oil and gas operations, power generation sites, and other heavy-duty applications since 1957.

RUNNING A SUCCESSFUL BUSINESS

About L&M Radiator

L&M Radiator leads the industry in engineering, designing, and manufacturing high-performance flexible core cooling and heat transfer solutions. Your heat transfer needs require continuous improvement that is why our commitment is offering one of the most advanced, comprehensive ranges of purpose-built cooling and heat transfer solutions today.

We at L&M Radiator make sure that we engineer the cooling system that will meet and exceed your application and environmental requirements from the extreme cold ambient of -50C to extreme high ambient +50C, High Altitude to deep underground, from the middle of the desert to the centre of ocean our MESABI® cooling systems are engineered and designed to meet your requirements, we work with all the OEM’s globally both large and small and also with independent clients all over the world providing MESABI® cooling solutions for your equipment and application.

Always specify MESABI® for your new procurements of mobile, stationary, fixed plant, equipment and experience THE MESABI® DIFFERENCE.

NEED MORE INFO? SUBMIT YOUR DETAILS & WE’LL BE IN TOUCH SOON!

Need more information? Call us on +61 8 9230 4400 to speak with one of our experts.